Description

Rotary Bakery Oven: Advanced Technology for Transforming the Bread Industry

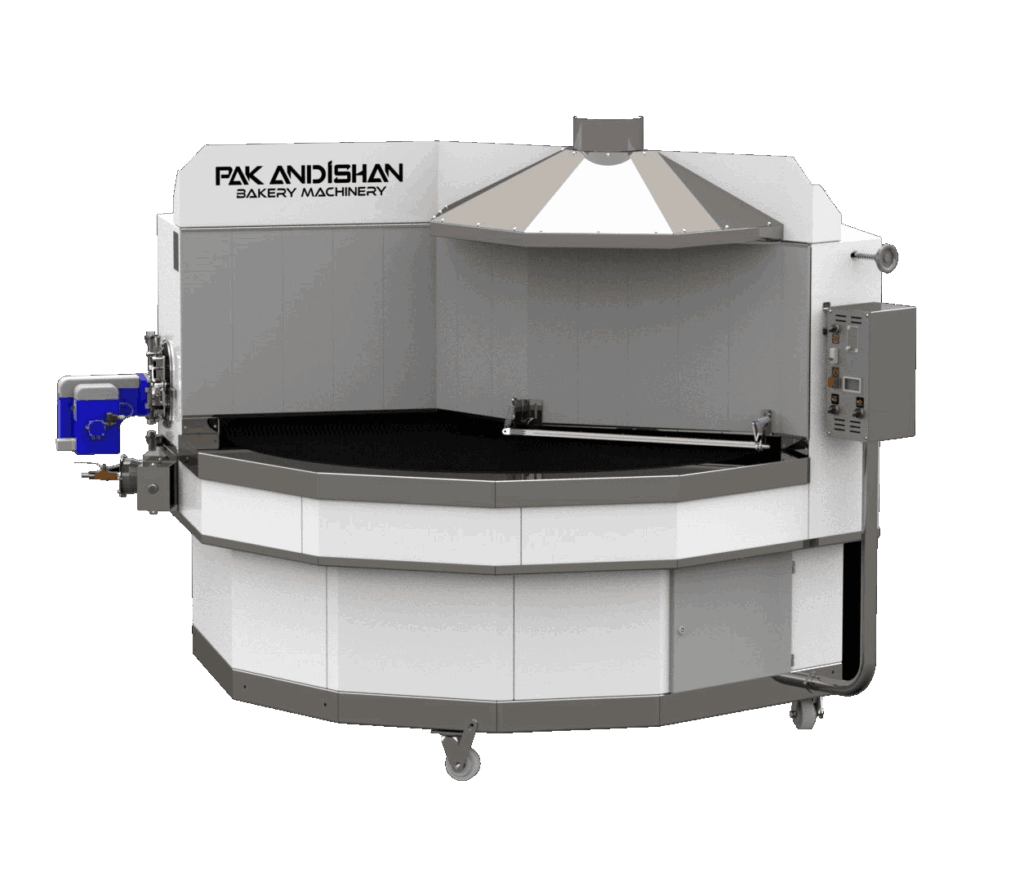

In the bakery industry, productivity, quality, and standardization are key factors for success. The rotary bakery oven, as an advanced baking device, has revolutionized the bread baking process, enabling the production of high-quality, consistent bread on a large scale. Known by names such as rotary bakery oven, rotary restaurant oven, and gas rotary oven, this rotating technology has set new standards in baking. Pak Andishan Company, by offering various models of rotary ovens, helps bakers, restaurateurs, and industrial producers take their businesses to the next level.

This page from Pak Andishan (the largest manufacturer of bakery equipment in the country) covers every aspect of the rotary bakery oven—from pricing and purchasing to technical specifications, benefits, applications, and economic analysis. The goal is to provide a complete guide for those looking to buy a Pak Andishan rotary oven and get familiar with this advanced technology.

What is a Rotary Bakery Oven?

A rotary bakery oven is a modern bread-baking device that uses a rotating system to produce uniform, high-quality bread. It automates traditional baking processes and delivers soft, consistent-textured bread. Designed for local bakeries, restaurants, and bread production factories, this device is also referred to as a rotary baking machine or gas rotary oven.

Various models are available for different needs. The compact rotary oven is ideal for small bakeries with a capacity of 500 to 1,000 loaves per hour and takes up little space. The rotary restaurant oven is tailored for restaurants and catering services needing fresh, high-quality bread like Lavash or Taftoon with a soft, tender texture. For traditional bread types, there are dedicated models such as rotary ovens for Barbari or Taftoon bread, with adjustable settings for thickness and texture. Industrial models, like the rotary bakery oven, serve large-scale factories with a capacity of 2,000 to 5,000 loaves per hour, enabling mass production for supermarkets and export markets.

Unlike traditional ovens, where baking quality depends on the baker’s skill and environmental conditions, the rotary oven uses a rotating system and digital control to ensure consistent quality. With optimized energy consumption and production speeds up to 10 times faster than traditional ovens, this device is a highly efficient solution for professional bakers. The advanced technology of the rotary oven not only increases productivity but also significantly reduces labor costs by minimizing human dependency.

Introducing Pak Andishan Rotary Oven

Innovations by Pak Andishan in Rotary Ovens

The Pak Andishan rotary oven, equipped with cutting-edge technology, has elevated industry standards. Its rotating baking system distributes heat evenly across the bread surface, producing bread with a soft, uniform, and high-quality texture. This feature is crucial for restaurant-grade or export-quality bread. A digital touch panel allows precise control over temperature, rotation speed, and bread thickness, making it ideal for a wide variety of breads—from thin restaurant bread to thick packaged bread.

The oven’s body is made of high-quality stainless steel, ensuring durability under heavy-duty conditions. It reduces operational costs by up to 40% compared to traditional ovens due to its energy-efficient design. Advanced safety sensors prevent potential accidents, while the internal cooling system maintains bread quality during mass production. Combined with ergonomic design and smart capabilities, the Pak Andishan rotary oven is a smart investment for bakeries.

Pak Andishan also offers customization options. Bakers can request add-ons like automatic packaging systems or custom settings for traditional bread types (e.g., rotary ovens for Barbari or Taftoon). This flexibility, along with extensive after-sales service, makes Pak Andishan a leading brand in the market.

| Feature / Specification | Description |

|---|---|

| Device Name | Automatic Rotary Bakery Oven |

| Main Use | Baking traditional breads (Lavash, Taftoon, Barbari) and pizza |

| Baking Method | Rotary – Baking on rotating plates |

| Fuel Type | Gas and diesel (interchangeable with burner change) |

| Heating System | Two direct flame burners (above and below the plates) |

| Portability | Crane-movable for relocation |

| Baking Chamber | Equipped with traditional bricks to preserve classic baking quality |

| Add-on Equipment | Compatible with automated bread-removal system |

| Energy Consumption | Low power usage with inverter system |

| Motor | Silent, long-life electrogearbox |

| Certifications | ISO 9001 & CE (Europe) certified |

| Installation & Training | Installed by technical experts + full training + initial testing |

| Warranty & Services | 6-month warranty – 10 years of after-sales service |

| Manufacturer | Pak Andishan Company |

Advantages of the Rotary Bakery Oven

The rotary bakery oven significantly enhances productivity and product quality with its advanced features. It allows the production of 500 to 5,000 loaves per hour, increasing speed up to 10 times that of traditional ovens. Precise temperature and rotation control produce soft, uniform-textured bread that ensures customer satisfaction. This consistency is especially valuable for bakeries focused on branding and building customer trust.

Automating the baking process reduces labor needs by up to 65%, significantly cutting operational costs. For example, a bakery in Tehran that adopted the Pak Andishan rotary oven reduced its staff from 6 to 2 people and increased daily output from 600 to 2,500 loaves. Eliminating hand contact during baking improves hygiene standards and minimizes contamination risks—crucial for restaurants and factories operating under food safety regulations.

Moreover, the rotary oven’s energy efficiency reduces gas and electricity expenses. Combined with its eco-friendly design and reduced bread waste thanks to uniform baking, the rotary bakery oven is a sustainable choice for modern businesses.

Introduction to Pak Andishan Rotary Oven

ویژگی های تنور دوار نانوایی

- قابل انتقال توسط جرثقیل به مکانهای مختلف

- دارای چرخ های مناسب جهت جابجایی آسان در نانوایی

- استفاده از آجر در محفظه پخت جهت حفظ خصوصیت سنتی فر

- قابلیت نصب دستگاه نان درآر

- مصرف کم برق به دلیل وجود اینورتر

- دارا بودن الکتروگیربکس بدون صدا با عمری طولانی

- قابلیت استفاده از هر دو نوع سوخت گاز و گازوئیل

- مستقیم بودن حرارت در دوار

- دارا بودن ۱۰ سنگ چدن در تنور

- نمای جلو استیل و رنگ تنور کوره ای چکشی می باشد

- داخل دوار از آجر نسوز، بدون استفاده از مصالح، دور تا دور آجر نسوز، پشم سنگ است

- دارای تیغه نان درآر برای جدا شدن آسان نان از تنور

- وجود دستگیره دریچه هوا برای خروج حرارت اضافی تنور به منظور جلوگیری از سوختن نان

- وجود ورقی سفید رنگ زیر سنگ های دوار جهت حفظ گرمای تنور

- مجهز بودن دستگاه به سنسور، هنگام بالا رفتن دما تا ۳۰۰ درجه موجب خاموش شدن خودکار مشعل بالا می شود

Technical Specifications of the Rotary Bakery Oven

Weight: 1206 kg

Power Supply: 220V, single-phase

Electro Gearbox Power: 0.75 kW

Production Capacity (per 8 hours): 500–600 kg

Dimensions (Diameter × Height): 220 × 203 cm

Model: POM007

Installation and Setup of the Rotary Oven

Installation and setup of all Pak Andishan machines are provided free of charge and carried out by the company’s experienced technicians.

All machines come with 10 months warranty and 10 years after-sales service.

How to Purchase the Rotary Oven from Pak Andishan

Available with both cash and installment payment options

Free installation and setup by the after-sales service team

All machines are certified with the Iran National Standard Mark, European Certificate (CE), and ISO 9001

For price inquiries, free consultation, distributorship requests, and bakery setup services, please contact:

+98 996 078 6617

Reviews

There are no reviews yet.